|

SCADA System – Introduction, History, Applications & Role in Industry Published on July 09, 2025 | Category: Introduction Share this Page:

SCADA, or Supervisory Control and Data Acquisition, is a sophisticated automation system used across industries to remotely monitor, control, and analyze real-time operational processes. These systems integrate both software and hardware to collect data from field instruments and remote equipment, providing centralized visibility and control over complex industrial operations. SCADA enables operators to respond swiftly to alarms, optimize process efficiency, and maintain product quality. Widely deployed in sectors such as energy, oil and gas, water treatment, manufacturing, and pharmaceuticals, SCADA systems offer critical insights into performance trends and system behavior. By bridging the physical and digital worlds, SCADA empowers industries to enhance safety, reduce downtime, and ensure seamless operations even across geographically dispersed facilities. Whether it's managing utility grids, controlling chemical batch processes, or supervising large-scale infrastructure, SCADA remains a core element in modern industrial automation strategies. What is SCADA?SCADA stands for Supervisory Control and Data Acquisition. It is a computer-based system used to monitor and control industrial processes remotely. SCADA systems are widely used in industries such as power plants, water treatment, oil & gas, manufacturing, and transportation. A typical SCADA system collects real-time data from sensors, PLCs, and RTUs (Remote Terminal Units), processes this data, and displays it on Human-Machine Interfaces (HMIs) for operators to monitor and control equipment. SCADA helps improve operational efficiency, safety, and decision-making by providing visualization, alarms, historical trends, and remote access capabilities.

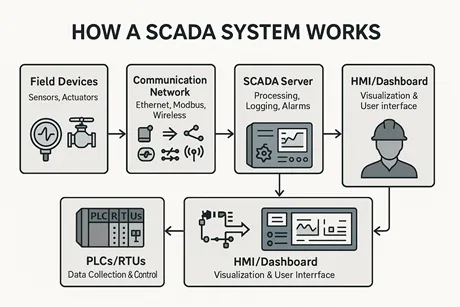

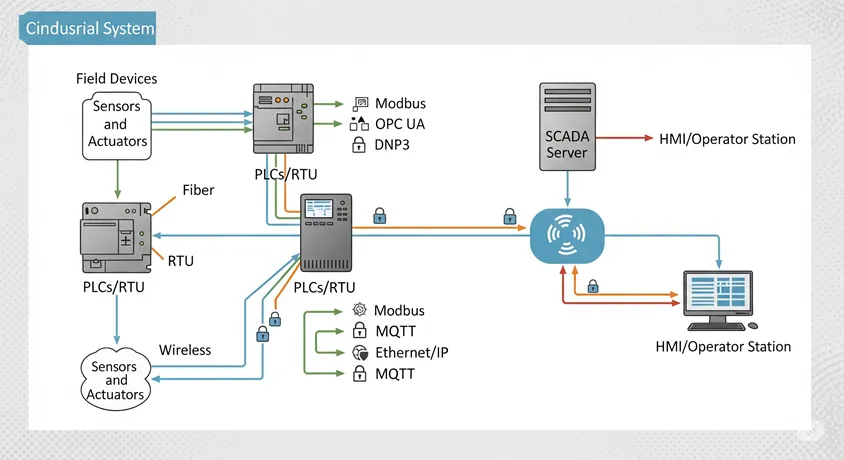

SCADA software (Supervisory Control and Data Acquisition software) is an industrial automation tool that helps monitor, control, and analyze real-time data from remote field devices like PLCs and RTUs. It forms the brain of a SCADA system, offering visualization, alarms, trending, and data logging capabilities. SCADA software allows operators to remotely control equipment and optimize industrial processes for efficiency and safety. Latest SCADA Software and Their Current VersionsHere is a list of widely used SCADA software platforms along with their latest versions as of 2025: Siemens WinCC (TIA Portal) – WinCC Unified V18 AVEVA System Platform (formerly Wonderware) – 2023 Release GE iFIX SCADA – Version 2023 Ignition SCADA by Inductive Automation – Ignition 8.1.38 Rockwell FactoryTalk View – FactoryTalk View SE v14.00 Schneider Citect SCADA – Version 2018 R2 Movicon.NExT SCADA – Version 4.2 Each SCADA solution offers unique features for real-time monitoring, IIoT (Industrial Internet of Things) integration, and support for modern communication protocols like OPC UA, Modbus, and MQTT. Choosing the right software depends on the application scale, platform compatibility, and industry-specific requirements. What Does SCADA Stand For?SCADA stands for Supervisory Control and Data Acquisition. It refers to a type of industrial automation system used to monitor, control, and collect real-time data from equipment and processes. SCADA systems enable centralized control and supervision of industrial operations such as water treatment, manufacturing, oil and gas, power generation, and building automation. The term breaks down as follows: Supervisory – Monitoring and managing systems at a high level. Control – Sending commands to field devices like PLCs and actuators. Data Acquisition – Collecting real-time data from sensors, meters, and controllers. SCADA plays a vital role in improving efficiency, ensuring safety, and supporting decision-making in large-scale industrial systems. How Does a SCADA System Work?A SCADA (Supervisory Control and Data Acquisition) system works by continuously collecting real-time data from machines and devices in the field, such as sensors and actuators. This data is collected by local controllers like PLCs (Programmable Logic Controllers) or RTUs (Remote Terminal Units), which are responsible for processing signals and executing control logic. The processed data is then transmitted to a central SCADA server through communication networks using protocols like Modbus, Ethernet/IP, or OPC UA. Once the data reaches the SCADA server, it is logged, processed, and monitored for alarms or abnormal conditions. The SCADA software converts this data into visual formats such as graphs, live dashboards, and process diagrams using HMI (Human Machine Interface) screens. This allows operators to monitor the entire plant or system from a central location in real-time. SCADA not only displays data but also allows remote control. Operators can send commands back to the PLCs to start/stop motors, adjust setpoints, or shut down systems during emergencies. This two-way communication—data acquisition from the field and command issuance to devices—is the core of SCADA functionality. By exchanging data in real-time with PLCs, SCADA ensures accurate process monitoring, improves decision-making, increases safety, and enhances operational efficiency. It's used in industries such as power generation, oil & gas, manufacturing, water treatment, and many more where centralized monitoring and control are essential.

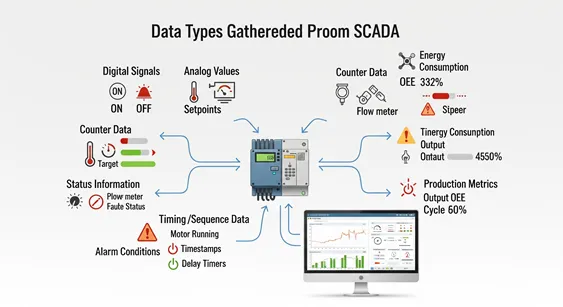

SCADA systems collect a wide range of real-time and historical data to monitor and control industrial processes. This data helps operators understand system performance, detect issues, and make decisions efficiently. Below are the main types of data collected: Digital (Discrete) Signals: ON/OFF status of switches, relays, motors, sensors, limit switches, alarms, etc. Analog Values: Continuous measurements such as temperature, pressure, level, flow rate, voltage, and current. Setpoints: Target values for control loops (e.g., desired temperature, tank level, or motor speed). Counter Data: Pulse counts from flow meters, shaft encoders, or batch counters used in production tracking. Status Information: Health or running state of devices (e.g., motor running, valve open, fault active). Alarm Conditions: Warnings or fault signals triggered when a parameter exceeds a threshold (e.g., high temperature). Timing and Sequence Data: Timestamps, delays, or sequence stages for time-sensitive operations. Energy Consumption: Power usage statistics collected from energy meters or VFDs integrated with PLCs. Production Metrics: Total output, production rate, downtime, machine cycle time, efficiency indicators (OEE). SCADA uses this data to update HMI screens, generate alarms, log historical trends, and issue control commands back to PLCs. This seamless data exchange forms the backbone of industrial automation and real-time decision-making.

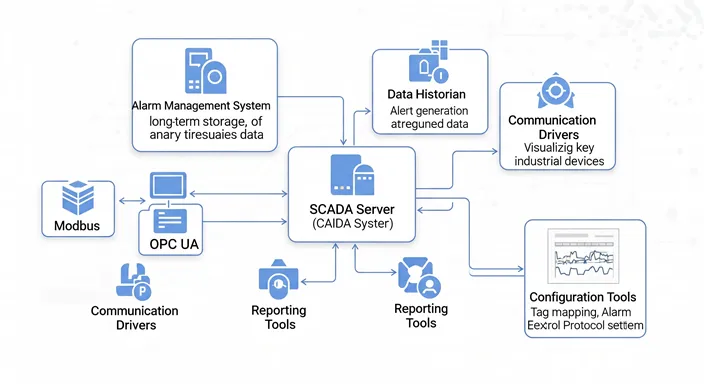

SCADA software is the core of the system, responsible for collecting, processing, visualizing, and storing data. It also enables user interaction and control through HMI (Human-Machine Interface). The main software components include: SCADA Server: Central software that manages data collection, historical logging, real-time monitoring, and alarm processing. Data Historian: Stores time-series data for trend analysis, reporting, and long-term performance evaluation. Alarm Management System: Triggers and logs alerts based on pre-set thresholds or fault conditions. Communication Drivers: Software protocols that enable SCADA to communicate with PLCs, RTUs, and other field devices (e.g., Modbus, OPC UA, Ethernet/IP). Reporting Tools: Generate automated or on-demand reports for compliance, diagnostics, and efficiency tracking. Configuration Tools: Used to design screens, define alarms, set tags, and configure device communications.

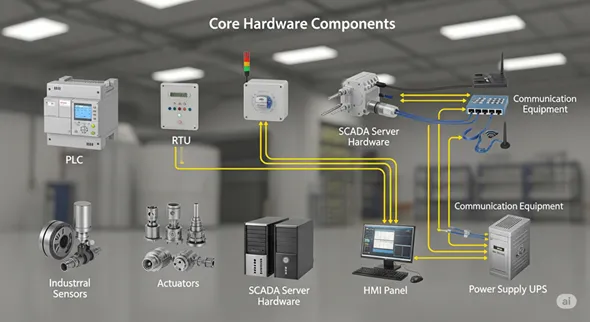

SCADA hardware forms the physical infrastructure that supports monitoring, communication, and control. It connects field equipment to the software layer and enables real-time data acquisition. The main hardware components include: PLCs (Programmable Logic Controllers): Industrial controllers that receive signals from sensors and execute control logic. RTUs (Remote Terminal Units): Microprocessor-based devices used to collect data and send it to the SCADA system, especially in remote areas. Sensors and Actuators: Devices that measure physical variables (e.g., pressure, flow) and perform actions (e.g., opening a valve). HMI Panels: Touchscreen displays or industrial monitors used by operators to view and control processes locally. Communication Equipment: Routers, switches, gateways, and communication cables (Ethernet, serial, fiber) that connect devices and servers. SCADA Server Hardware: Computers or servers that run SCADA software, host databases, and manage operator interactions. Power Supply Units (PSUs): Ensure stable power to critical components, often with backup batteries or UPS systems.

Communication is the backbone of any SCADA (Supervisory Control and Data Acquisition) system. It enables the exchange of real-time data between field devices (like sensors, actuators, PLCs, and RTUs) and the central SCADA server or control center. Effective communication ensures timely monitoring, control, and decision-making across the entire industrial process. 1. Field CommunicationSCADA systems rely on industrial communication protocols to transmit data between field devices and controllers (PLCs/RTUs). Common field-level protocols include: Modbus (RTU/TCP): Widely used, simple, and efficient for serial or Ethernet-based communication. Profibus/Profinet: Popular in Siemens-based systems for fast and reliable data exchange. Ethernet/IP: Used in Allen-Bradley and Rockwell Automation systems for real-time Ethernet communication. CAN bus: Common in vehicle systems and embedded control networks. 2. Network CommunicationSCADA uses various networks to connect remote stations, PLCs, and operator stations: Ethernet LAN/WAN: For high-speed communication in plant-wide systems. Fiber Optic Networks: For long-distance, noise-immune communication in harsh environments. Wireless Communication: Wi-Fi, radio, or cellular (4G/5G) used in remote or mobile SCADA systems. 3. SCADA to Server CommunicationData collected by PLCs/RTUs is sent to the SCADA server using standard industrial protocols such as: OPC UA (Open Platform Communications – Unified Architecture): Modern, secure, and platform-independent. DNP3 (Distributed Network Protocol): Common in utility industries like water and power. MQTT: Lightweight protocol used in IoT and cloud-integrated SCADA systems. 4. Data Security and ReliabilitySCADA communication must be secure and reliable. Techniques like VPNs, firewalls, data encryption, and redundancy (dual communication paths) are used to protect critical infrastructure from cyber threats and communication failure. In summary, SCADA communication combines fieldbus protocols, industrial Ethernet, remote access technologies, and secure server communications to provide seamless and continuous monitoring and control across industrial environments.

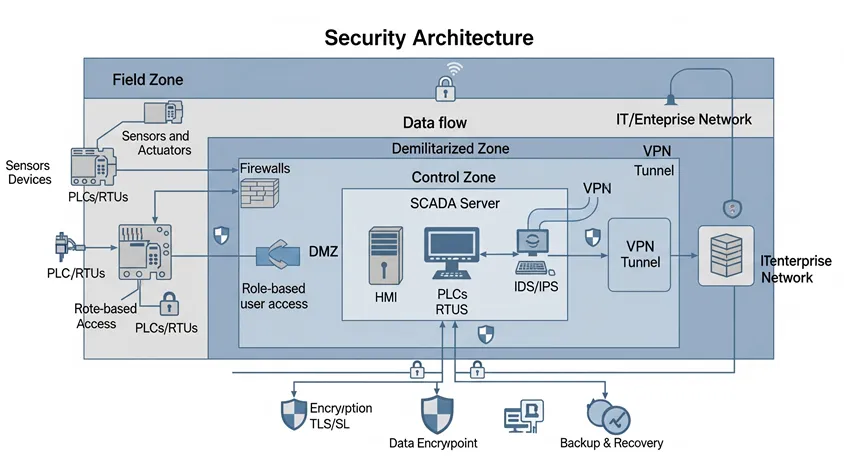

SCADA systems control critical infrastructure and industrial operations, making them a target for cyber threats. To ensure the safety, reliability, and integrity of these systems, SCADA security features are implemented to protect against unauthorized access, data breaches, and operational disruptions. 1. User Authentication and Role-Based AccessOnly authorized personnel can access the SCADA system. Role-based access ensures users can only perform actions relevant to their responsibility (e.g., operator, engineer, administrator). 2. Data EncryptionData transmitted between field devices, PLCs, and SCADA servers is encrypted using protocols like TLS/SSL or VPN tunnels to prevent data interception and tampering. 3. Firewalls and Network SegmentationFirewalls are used to control traffic between SCADA networks and external systems. Network segmentation isolates critical SCADA components from corporate IT networks to reduce exposure. 4. Intrusion Detection and Prevention Systems (IDS/IPS)SCADA networks use IDS/IPS tools to monitor for unusual activity, detect cyberattacks, and automatically block malicious traffic. 5. Secure Protocols and PortsOnly essential communication protocols (e.g., OPC UA, Modbus TCP, DNP3 Secure) are allowed, and unused ports are disabled to minimize entry points. 6. Patch Management and System UpdatesRegular updates and patches are applied to SCADA software, firmware, and operating systems to fix vulnerabilities and improve resilience against threats. 7. Audit Trails and LoggingSCADA systems keep detailed logs of user actions, alarms, and system changes. These logs help in detecting unauthorized access and tracking system activities for compliance. 8. Physical SecurityControl rooms, PLC cabinets, and servers are protected with physical barriers, access controls, and surveillance to prevent unauthorized physical access. 9. Backup and Disaster RecoveryRegular backups of configuration, data, and control logic are maintained. Disaster recovery plans ensure the SCADA system can be restored quickly after an incident. 10. Cybersecurity Standards ComplianceModern SCADA systems comply with standards like ISA/IEC 62443, NIST, and NERC CIP to ensure best practices in security and risk mitigation. Implementing these security features helps safeguard SCADA systems from both internal and external threats, ensuring continuous, safe, and reliable industrial operations.

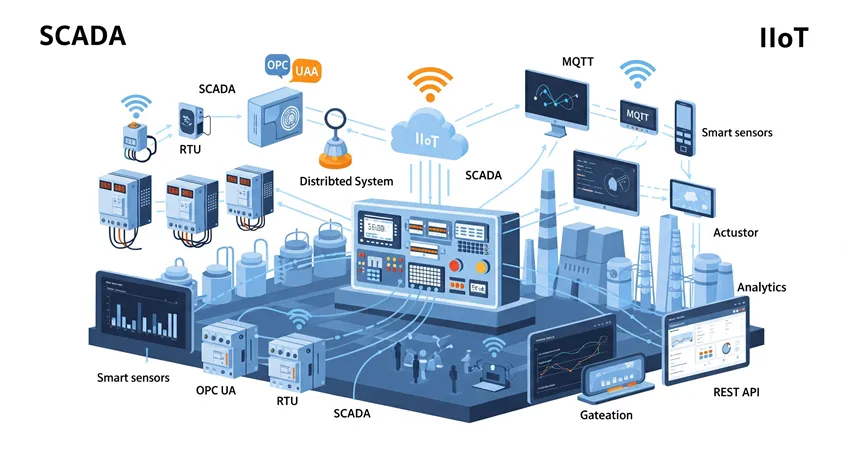

SCADA (Supervisory Control and Data Acquisition) plays a crucial role in the Industrial Internet of Things (IIoT) by serving as the connection between traditional industrial automation systems and modern cloud-connected technologies. While SCADA systems handle real-time data collection, monitoring, and control from field devices, IIoT platforms analyze this data using cloud computing, machine learning, and big data techniques. By integrating with IIoT, SCADA systems can: Transmit live process data to cloud dashboards and analytics platforms Enable predictive maintenance and data-driven decisions Provide remote access to operators and engineers via mobile and web Improve energy efficiency, production quality, and operational insight SCADA acts as the data gateway, helping legacy systems become part of the digital industrial ecosystem through secure protocols like MQTT, OPC UA, and REST APIs.

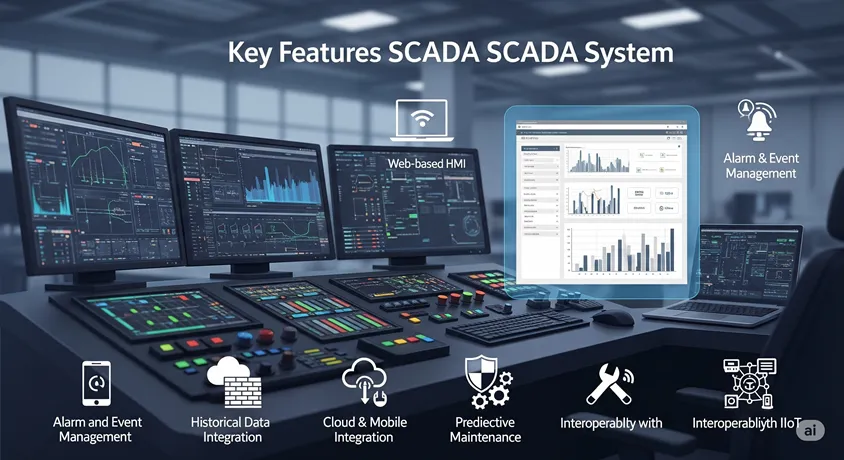

Modern SCADA systems have evolved beyond local control rooms. They now provide cloud connectivity, mobile access, and advanced automation capabilities. These features enhance performance, scalability, and integration with smart technologies. Key features of a modern SCADA system include: Real-time process monitoring and control Web-based HMI dashboards with remote access Integrated alarm and event management Historical data logging and trend analysis Cloud integration and mobile device access Cybersecurity (encryption, access control, firewalls) Support for open standards (OPC UA, Modbus, MQTT) Predictive maintenance with analytics and AI These capabilities make SCADA systems more adaptable, secure, and connected to the wider IIoT environment.

SCADA systems are used across various industries to monitor, control, and automate operations. These systems provide real-time visibility and control, helping improve efficiency, reduce downtime, and enhance safety. Common industrial applications of SCADA include: Power Generation and Distribution: Monitoring substations, transformers, and grid stability. Water and Wastewater: Automating pumping stations, treatment plants, and reservoir management. Oil and Gas: Pipeline monitoring, leak detection, and well control. Manufacturing: Supervising assembly lines, machine status, and production tracking. Building Automation: Managing HVAC systems, lighting, elevators, and energy usage. Transportation: Controlling traffic systems, railways, and airport operations. Each of these sectors benefits from SCADA’s ability to visualize operations, log historical performance, and issue remote commands for real-time control.

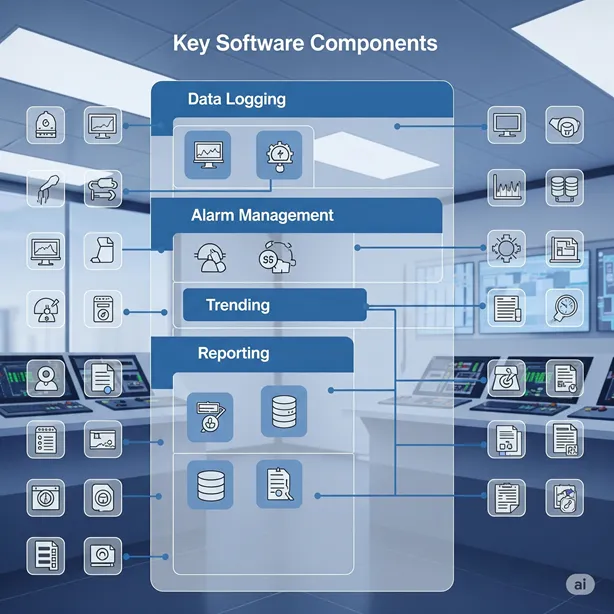

A SCADA system is powered by several critical software components that enable real-time monitoring, control, data analysis, and decision-making in industrial environments. These components work together to provide visibility, reliability, and operational efficiency. 1. Data Logging: SCADA continuously collects and stores real-time process values (e.g., temperature, pressure, flow) from field devices into databases or historians. This data is used for diagnostics, compliance, and trend analysis. 2. Alarm Management: SCADA alerts operators when process parameters exceed safe or defined limits. It supports prioritization, acknowledgment, history logs, and visual/audio indicators to ensure timely response to critical events. 3. Trending: Real-time and historical data trends are plotted as graphs or charts. Operators can view changes in process variables over time to detect patterns, anomalies, and optimize control strategies. 4. Reporting: SCADA can automatically generate reports summarizing production data, alarms, system status, and efficiency. These reports can be exported as PDFs or spreadsheets and are crucial for performance tracking and audits. Together, these components enable a SCADA system to provide actionable insights, maintain safety, and enhance productivity across various industrial sectors.

|